Low Gross Profit Margin

So you've analyzed your cost structure and have become certain the issue isn't in controllable overheads or fixed asset structure and there's only one place left to turn. The gross profit margin on the products you're selling just isn't enough. Gross profit is calculated as the sales price minus the direct and allocated cost to produce the product.

Gross profit margin has three components.

Are you charging enough for your product?

Are costs low enough to sustain the price you're charging?

Is the mix of products offered rich enough to sustain the business?

See if any of these issues sound familiar.

Pricing is too low

No aspect of your business can impact the bottom line of your business-like pricing yet it’s the part of a business management tiptoes around instead of facing head on. Where does your product lie in the marketplace? Remember, lower costs is not a sustainable strategy if there is more than one business competing in the same arena for lowest cost. Try understanding your market and pricing your goods for what the consumer is willing to pay. Consider specific niches that command a higher price than the general market. Make sure you’re not pricing on a cost+ model, truly assess the value of your product.

Consider the compensation structure of your sales team. Are you encouraging the right behaviors? Make sure you are incentivizing them to sell the most profitable products, not just volume.

Costs are too high

When the research has been done and pricing is in line with the market yet you’re still not commanding the margins needed to be profitable you then have to questions your costs. It could be because your cost structure is not aligned with your market. Some ways this shows itself in a business is when there are bottlenecks in the manufacturing causing idle time in equipment and the workforce. This could also be because you need a leaner manufacturing facility.

Generally speaking the cause of an out of line cost structure in a business needs to be teased out through analysis of shop floor activities over time and identifying what parts of the manufacturing process is causing inefficiency in that process or downstream processes. Often identifying the issue in a manufacturing plant does require skilled expertise in cost accounting and industrial engineering. However, you could start by running daily production reports and comparing production outputs. See what the best output days have in common. Try to understand what processes are the most costly and consider outsourcing or modifying that process.

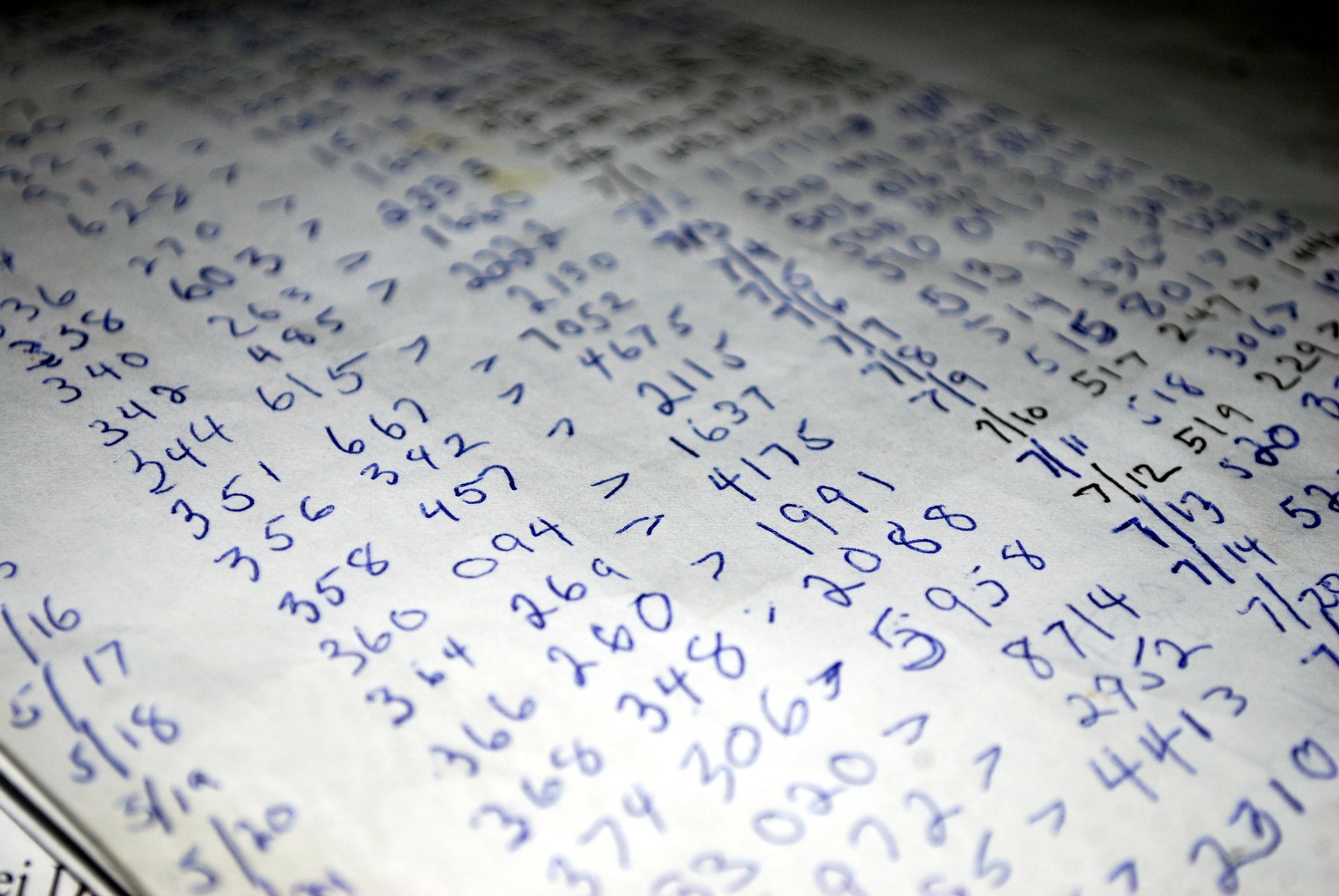

One added tip is that anytime you can view your costs visually you may understand them better and have better actionable items.

Product mix is not rich enough

Most businesses sell more than one product. Often they sell loss leading products because it gets them in the door with a customer and then follow up with more profitable products. Just remember that you can’t make up losses from material with volume. Volume only makes the problem worse.

To ensure the mix is heavy enough on profitable products, you first must identify profitable products. Sometimes product profitability is complicated because it’s profitable to one customer but not another. This is an analytical study that can be done and odds are your ERP system already has the information inside and it just needs to be teased out with reports and queries.

When the most profitable products are known a business can then incentivize the sales team to sell the most profitable items. To ensure the most profitable products and orders are being placed a business needs to regularly run sales reports. The higher the volume the more frequently these reports should be ran.

Product features are not in line with what the customer values

Do you know what your customer wants? Businesses who are out of touch with their customer often add costly features to products because they assume their customer has certain desires they may not actually have. Canvas your customers and review sales information to understand trends in your marketplace. Some of the most innovative businesses are not innovative because of what features they add to their product, but instead what they remove from their product that reduces costs to the consumer.

Poor operations planning

Whether you do business planning on a perpetual annual cycle with a rolling 13-month plan, or you plan your business annually in 12 month cycles you can still can make mistakes. Often businesses fail to review the accuracy of their operations plans after they’re made and plan their workforce hiring seasons, machine capacities, inventory supply, raw material purchases, and more very poorly. This can all add up to at least one year or planning cycle of unnecessarily high costs.